Large-span continuous rigid box girder bridges often experience cracks of varying degrees during construction, making it difficult to control the quality of the bridge and posing hidden dangers for later operation. In the construction of large-span continuous rigid box girder bridges, there are various reasons for cracks. This article provides an introduction to the analysis of the causes of common crack problems and the implementation of preventive control measures in the construction of large-span continuous rigid box girder bridges.

There are several reasons for the early shrinkage cracks in concrete:

1) Influences of cement hydration heat: Some cement with a larger specific surface area has a faster hydration rate, concentrated heat release, and higher water demand, making it prone to shrinkage cracks during construction in summer.

2) Effects of admixture selection: Although admixtures can reduce the amount of mixing water, some poor-quality admixtures contain harmful substances that increase concrete shrinkage. This shortens the time from initial setting to final setting, leading to surface cracks due to rapid loss of moisture.

3) Effects of mix design: Insufficient cement content may result in concrete not meeting design strength requirements, while excessive cement content can lead to cracking. A high sand content in pumped concrete and inappropriate water-cement ratio selection can cause concrete to have poor workability, segregation, bleeding, and drying shrinkage, resulting in cracks.

Preventive measures include:

1) Choosing suitable cement grades and types;

2) stricter quality control of additives, with properly calculated rates to minimize the water-cement ratio. Smaller ratios mean less concrete shrinkage and greater overall crack resistance.

3) Optimize mixture proportionality for further reduction in cement usage and hydrated heat effects; controlling the sand and water-cement ratio meticulously.

Common crack causes in construction include:

1) Uneven concrete vibration result in poor uniformity and density, causing cracks.

2) Insufficient maintenance causes shrinkage cracks.

3) Overheat from large square footage of 0# block can lead to thermal cracking.

4) Excessive heat speeds up cement hydration leading to cracks.

5) Premature removal of the box grider formwork causes cracks.

Prevention measures:

1)Quick but gentle insertion of vibrator, shorter vibration period for best results, no overvibration or undervibration. Double vibration used to ensure dense concrete. Two post-placement surface smoothing reduces crack formation.

2) Plentiful early water conservation for new placed concrete, ground cloth covering ensuring surface moisture, minimizing early shrinkage.

3) Minimize time gaps between multiple pours in the build, performing at night during cooler temperatures. Overlapping box girder surface and water sprinkling with internal water storage for temperature control.

4) Avoid high concrete placement temperature during heatwave by pouring at night.

5)Strictly control the steel grider mold removal time to prevent cracks caused by premature beam mold removal.

Key causes of cracks are:

1) Premature tensile stressing due to lower than designed concrete strength and modulus.

2) Inadequate bedding between segments reducing connection capability.

3) Excessive moisture diffusion resulting in dry crack formation during new concrete pouring into precasted sections.

4) Slight restrictions imposed by previous segment on subsequent construction.

5) Longer intervals leading to larger age difference between consecutive sections.

Prevention measures include:

1) Tensile stressing post reaching designed concrete strength and modulus.

2) Focusing on thorough bed-prepping across segments for a stronger joint.

3) Spraying or humidifying the joint surface before completing new concrete cast, mitigating the prone zone change.

4) Preferring low shrinkage concrete to minimize cracking risks.

5) Clearly scheduling tasks to ensure continuous progress between segment beam.

The following cause for cracking includes:

1) Insufficient concrete cover beneath the prestressed steel bars in the base plate.

2) Substandard installation of baseboard reinforcement leading to poor integrity.

3) Internal and external temperature discrepancies due to differential solar exposure between the top and bottom plates.

4) Extended construction interval between blocks 0 and 1 causing contraction variance resulting in edge cracks.

Prevention measures include:

1) Proper installation of the prestressing pipeline at designed positions, meticulous fastening, ensuring adequate concrete thickness beneath

2) Control over quality of connection rebars of the closed stirrups and upper and lower main rebar;

3) Immediate chiseling of vent holes post-concrete pouring to regulate internal/external temperature differences.

4) Thorough preparation aimed at minimizing construction interval between blocks 0 and 1.

Significant Cracking Causes Include:

1) Uneven layering of the mold during placement causing thinning and cracking.

2) In the three-dimensional prestressed system,high vertical prestress loss may provoke high tensile stress leading to cracking. Major factors in this include poor ductility, short length, and extensive prestress loss in vertical reinforcing bars, uncontrolled tension release and leakage due to improper control, and inadequate compaction of grout and sealing of reinforcement due to late completion.

Preventive Measures:

1) Stringent control over the precision of beam mold installation, proper fastening and guaranteeing thickness.

2) Each vertical reinforcing bar must undergo a secondary tension after anchoring, adopting dual control of tension force and elongation, strictly ensuring the quality of grouting, and promptly compressing grout and sealing after tension release.

During tensioning, punching force is produced on the tooth plate concrete, resulting in cracks.

During construction, steel bars must be installed in strict accordance with the designed size and quantity, concrete vibration must be strengthened to ensure compactness, and maintenance must be strengthened after pouring is completed.

The main cause of the cracks is the irregular installation of reinforced steel bars behind the anchor, and the poor compactness and insufficient strength of the concrete at the anchor pad.

Reinforced steel bars should be installed according to the design, the concrete should be vibrated after strengthening the anchor pad, and the concrete should be tensioned after it reaches its strength.

Concrete can crack due to water shrinkage under boundary constraints and excessive external forces prior to reaching design strength.

Prevention methods include building a straight frame as per design, managing join temperature, executing concrete pouring at the lowest point of the day's temperature, incorporating modest expansion agents into the mix at the jointing segment, and providing solid aftercare post-pouring.

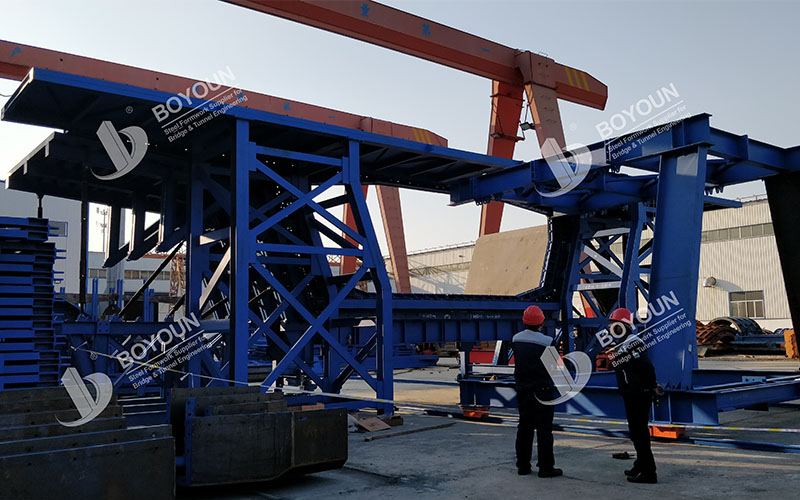

This study dissects the root causes and preventive measures of common cracking in long-span continuous rigid frame box girder bridge construction, discussing its impact due to concrete quality, construction techniques, and structural stress. Adopting quality-proven formwork from reputable formwork manufacturers and implementing effective construction methods are recommended to enhance smooth progression, minimize cracking incidents, and ensure safety during subsequent operations.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn