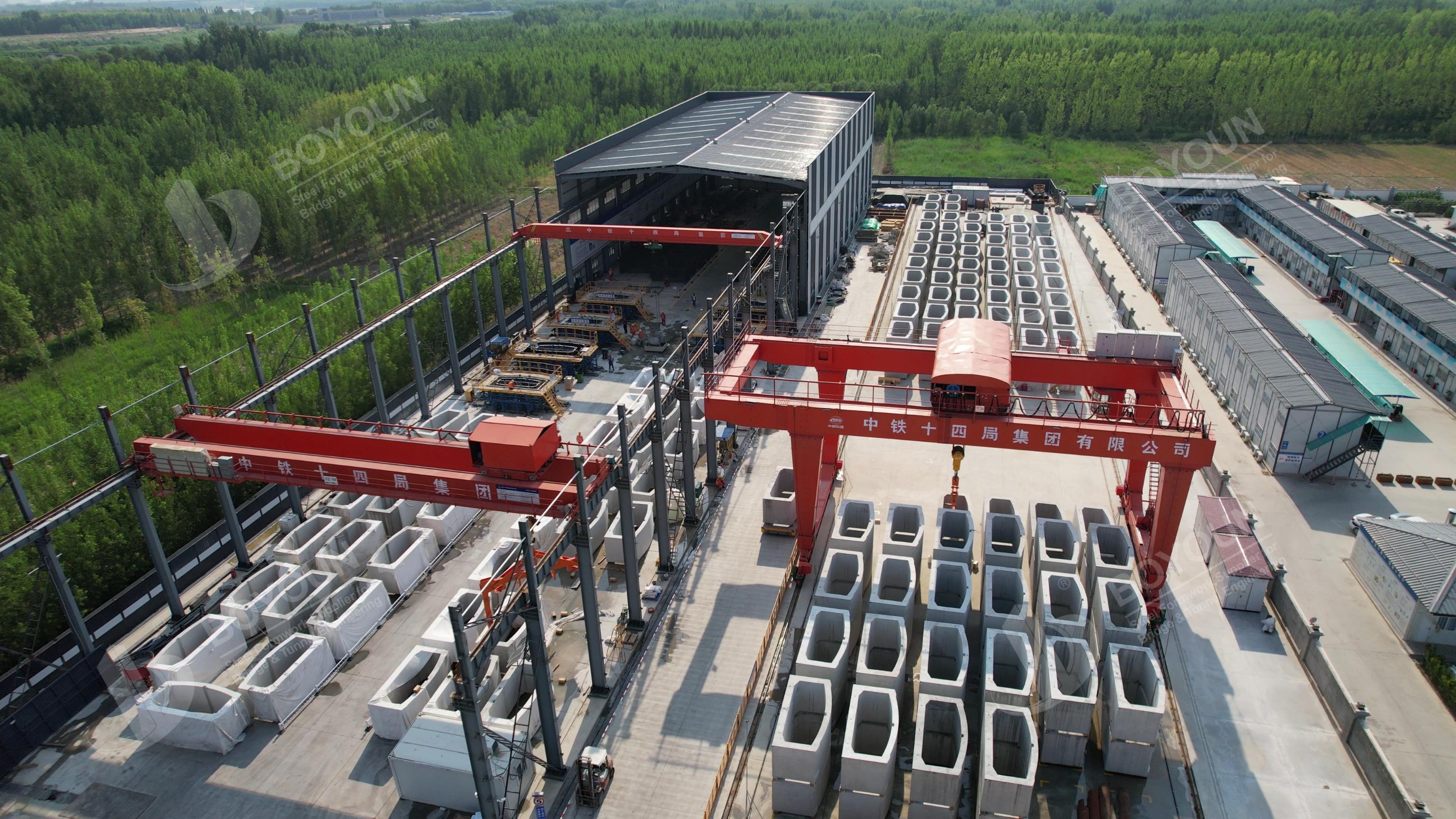

In October 2024, the precast box culvert "mouth" precast parts of the Huanggang Road Yellow River Crossing Tunnel Project in Jinan, the world's largest diameter underwater tunnel, successfully exceeded the 1,000-piece mark, laying a solid foundation for future tunneling of the subsequent shield machines.

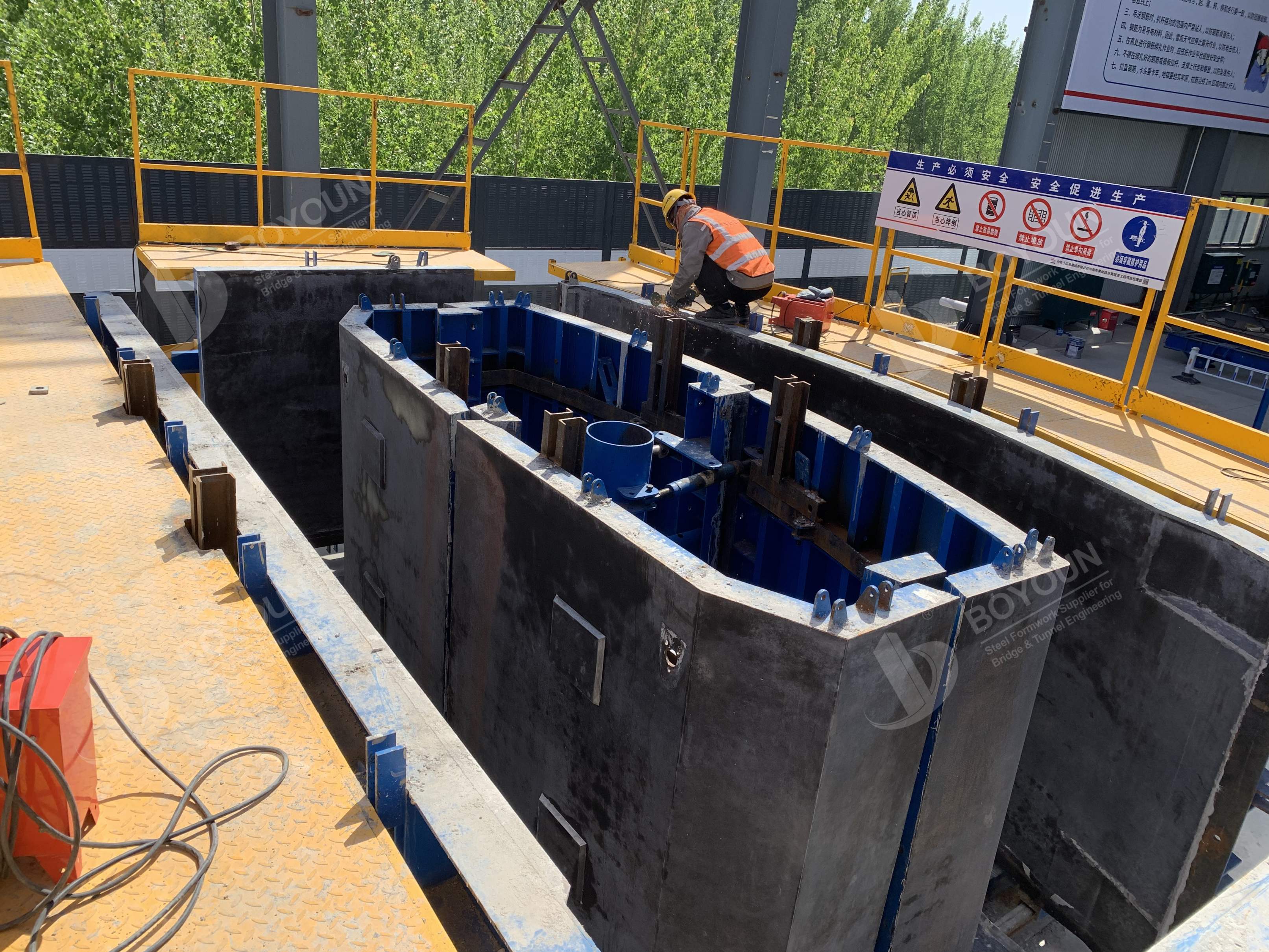

Boyoun supplied six sets of box culvert formwork for this project. The formworks are designed based on the vertical precasting process to account for the impact of structures such as positioning grooves, drainage ditches, and holes on precast components during product precasting. The formwork is designed according to the structure of the outer and inner formwork wrap bottom formwork. Quick connectors are set between formworks to facilitate rapid assembly. Pins and plates are positioned between outer formworks and inner formworks to control the overall size of the formworks and enable quick positioning and assembly. The inner and outer formworks use hydraulic cylinders for formwork demolding and erection. Thus, the overall precasting efficiency improves and can reach one mold per day.

How did a precast component factory of such a scale achieve standardized production?

The precast of the project box culverts adopts the "factory" processing mode. The production lines are separated, and each line is further divided into independent areas for steel bar binding, box culvert precast, box culvert storage, and box culvert transportation, resulting in "assembly line" operations. The project has introduced a large number of intelligent devices, such as CNC hoop bending machines and CNC bending machines, which has fundamentally solved the problem of quality control of prefabricated components and greatly improved processing efficiency and reduced labor input.

Before construction, training on subway engineering construction knowledge was provided to project management personnel and professional technicians. Three-level education was implemented to enhance their awareness of quality and safety. Prior to promoting new technologies, processes, equipment, and materials, relevant knowledge was also provided. Every work team on the project conducts 'pre-shift quality and safety education' every day, arranges the work deployment for the day, implements various work tasks, rectifies and inspects various problems that have emerged, ensuring that the team members are in a good mental state, and laying a strong foundation for the day's work.

The project adopts an intelligent curing system. With one key to start the intelligent curing system, the full-cycle curing construction can be automatically completed, minimizing the interference of human factors in curing, improving curing efficiency, and saving labor.

For hydraulic formwork construction, the outer formwork has achieved full hydraulic operation, greatly improving efficiency and reducing labor intensity of workers. Additionally, the outer formwork moves as a whole, keeping the construction site clean.

The construction of bridges and tunnels across the Yellow River has become the first major project in the development of northern area of Jinan on the other side of the Yellow River. It will provide strong transportation support for the major national strategy of the Yellow River, the transformation of old and new growth drivers, and the "Northern Development" of Jinan.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn