The previous article introduced the quality control measures for the intelligent tensioning of T beams in a broad sense. In addition, quality can also be controlled through specific operation steps. Let's take a look at them one by one.

The T beam pedestal must be marked with red paint prior to construction. The T beam design and reinforcing bar spacing should be measured and noted on the pedestal. Additionally, a steel bar positioning frame should be placed on both sides at intervals of about 5 meters to control the vertical spacing of the reinforcing bars. When laying the reinforcing bars in the horseshoe area, the main reinforcing bars should be spot-welded and fixed one by one. It must be spot welding or full binding, and skipping binding is strictly prohibited. Horizontal bars and stirrups can be manually bound. Only in this way can the stability of the steel bar framework be ensured, laying a solid foundation for the subsequent construction work.

(2) Steel Strand Penetration Operation

Steel strand penetration must be carried out strictly in accordance with the construction design drawings. Operate according to the coordinates marked on the drawings. It's important to note that the interval between the design drawings is mostly one coordinate per meter, but in the construction drawings, it is stipulated that a coordinate point needs to be set every 50 meters. In this case, we need to interpolate and adjust each point are required. The purpose of the adjustment is to make the corrugated pipe linear smooth and suitable. Then insert the extraction rod into the corrugated pipe to line the corrugated pipe. When the T beam concrete is poured, the corrugated pipe will not be deformed by the concrete of the beam body, which will hinder the threading and tensioning.

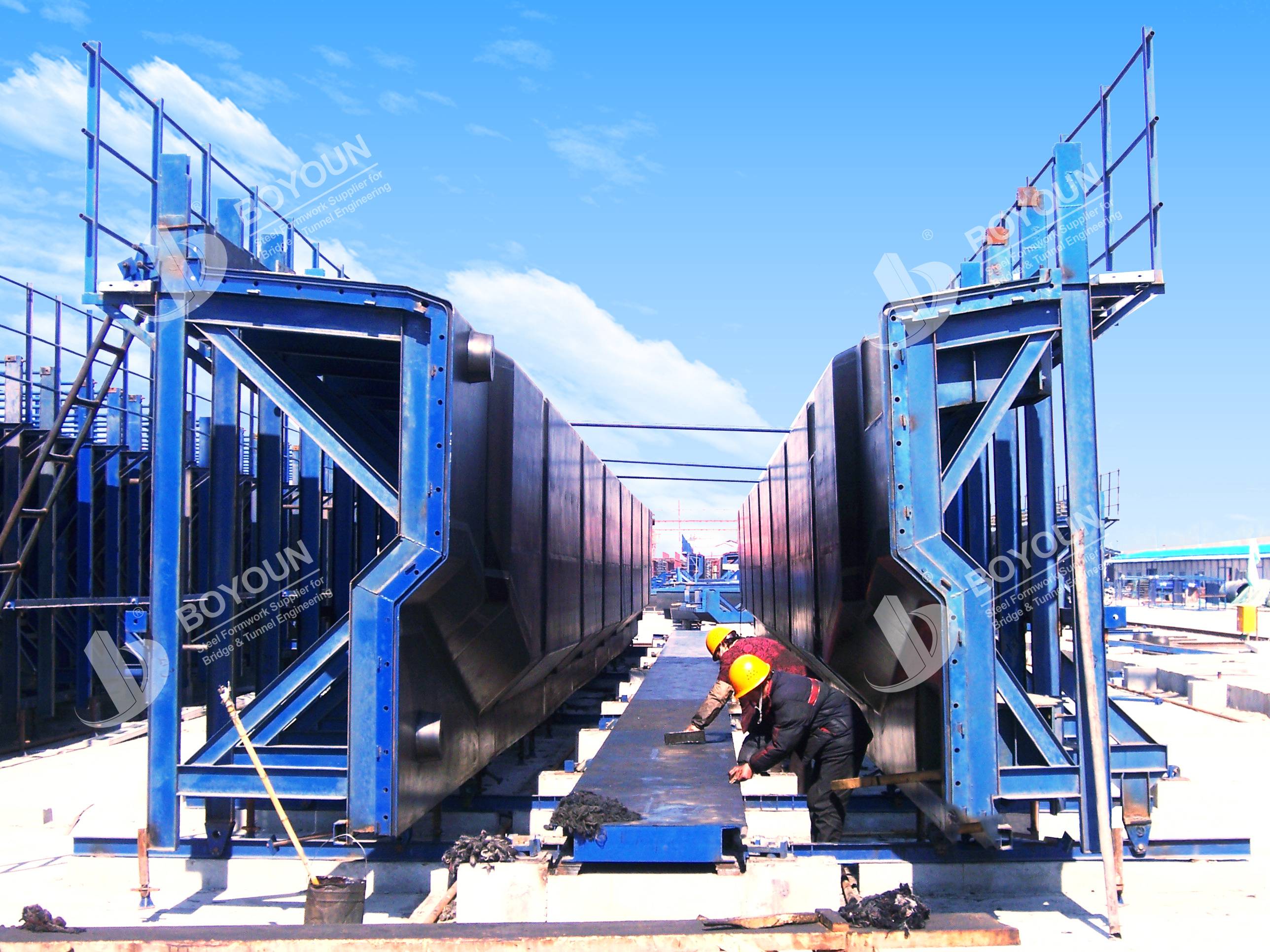

(3) Mold Closing

Mold closing is also a crucial step. Before mold closing, first, check the specific position of the piece beam on the bridge. If it is at the abutment support end of the bridge deck, the steel plate embedded at the bottom of the beam should consider the relationship between the bridge deck slope and the backing plate, and for different up and down slopes, 8 mm or 10 mm reinforcing bars should be padded. It 's important to check the flatness of the joint to ensure that it is within the specified range of the construction requirements, and then lock the formwork firmly. After this step is completed, it is the formal mold closing. Pass the reinforcing bars and tighten the bolts to install them firmly.

(4) Leak Stoppage

Usually, after the mold closing of the T beam, there are three parts that are prone to slurry leakage. One is the corrugated pipe orifice and embedded bars at the two ends of the formwork, the second is the embedded bars of the diaphragm, and the third is the embedded bars of the wet joint of the flange slab. All the holes that appear in the above mentioned three parts need to be tightly blocked with sealant. In terms of the appearance quality of concrete, this factor accounts for a considerable proportion and must not be ignored.

(5) Concrete Pouring and Tamping of T Beams

Before tamping the concrete, high-frequency vibrators should be installed on both sides of the T beam formwork. Note that the spacing should be controlled within 1.5-2.0 meters and arranged in a square shape. In terms of the tamping method, the combined use of an insertion-type tamping rod and a high-frequency vibrator is currently the most common and efficient way. Because in some parts, such as the beam end, horseshoe, and diaphragm, the effect of the latter is not obvious. In this case, the former is needed for vibration, and for the large-area vibration of concrete, the latter is more favorable. Therefore, by taking advantage of the strengths of both, and compensating for each other's weaknesses, the construction quality of the intelligent tensioning of T beams can be further improved.

(6) Mold Removal, Chiseling, and Maintenance

The most significant aspect of the mold removal step in construction quality is that it is easy to damage the concrete profile of the T beam. Removing the mold too early will cause damage to the profile, and removing it too late will make the mold removal operation more difficult. The determination of when to remove the mold is closely related to the local climate environment during construction and requires the construction personnel to master it appropriately based on experience and objective conditions. Generally speaking, it is most appropriate to remove the mold when the concrete strength reaches 2.5 MPa. The chiseling of concrete is to use an air pick to chisel the concrete at the two beam ends, diaphragms, and flange slabs. The depth should be controlled within 1.5-2.0 cm, and the chiseling area should be exposed to the new concrete surface to ensure the construction quality.After the mold removal of the T beam and the basic completion of all processes, sprinkling water for maintenance is also a key step to ensure the service life of the bridge.

To Sum Up

This article explains the specific operation steps for quality control of the intelligent tensioning of T beams, including marking the pedestal and steel bar binding, penetration operation of steel strands, mold closing, leak stoppage, concrete pouring and tamping, mold removal, chiseling, and maintenance. Each step has strict requirements and specifications to ensure construction quality. Every link in the construction of T beams is crucial. Construction personnel should strictly follow the operation specifications, pay attention to details. Let's approach each step with a rigorous attitude and professional skills, strive for high-quality T beam projects, and build safe and reliable bridges.

International Department: Room 2507-2508, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

info@boyoun.cn